THE BUILD

THE BUILD

JUMP TO

INTRODUCING THE

SKYRANGER NYNJA

Skyranger microlights have been around since the 90s, their simplistic yet rugged, dependable design and low operating costs earning them an enviable reputation across the world.

The Skyranger Nynja variant, designed by Flylight Airsports at Sywell aerodrome in Northamptonshire, features a number of advancements over the original design. Amongst numerous other improvements, the modular composite panels and vortex reducing wingtip fairings improve structural integrity whilst reducing aircraft weight and fuel burn.

Whilst Flylight offer a "factory-built" option, the Skyranger is also available as a kit that owners and builders must first piece together themselves.

So what does building a "kit-build" aircraft entail? Find out more below.

ABOUT THE SKYRANGER

Skyranger microlights have been around since the 90s, their simplistic yet rugged, dependable design and low operating costs earning them an enviable reputation across the world.

The Skyranger Nynja variant, designed by Flylight Airsports at Sywell aerodrome in Northamptonshire, features a number of advancements over the original design. Amongst numerous other improvements, the modular composite panels and vortex reducing wingtip fairings improve structural integrity whilst reducing aircraft weight and fuel burn.

Whilst Flylight offer a "factory-built" option, the majority of Skyranger owners purchase their aircraft as a kit to piece together themselves.

So what does building a "kit-build" aircraft entail? Find out more below.

BUILDING A

KIT-BUILD AIRCRAFT

In the words of Flylight, the Skyranger Nynja is "supplied as a pre-fabricated fast build kit. All necessary components are supplied, down to the small details, with all structural parts finished, and connecting brackets pre-assembled. No special skills or processes are required. Building is simple assembly work, guided by a comprehensive step by step build manual."

To find out more about my build, the challenges I face along the way, and how I find the "simple assembly work"(!), visit my blog.

BUILDING A

KIT-BUILD AIRCRAFT

In the words of Flylight, the Skyranger Nynja is "supplied as a pre-fabricated fast build kit. All necessary components are supplied, down to the small details, with all structural parts finished, and connecting brackets pre-assembled. No special skills or processes are required. Building is simple assembly work, guided by a comprehensive step by step build manual."

To find out more about our build, the challenges we face along the way, and how we find the "simple assembly work"(!), visit our blog.

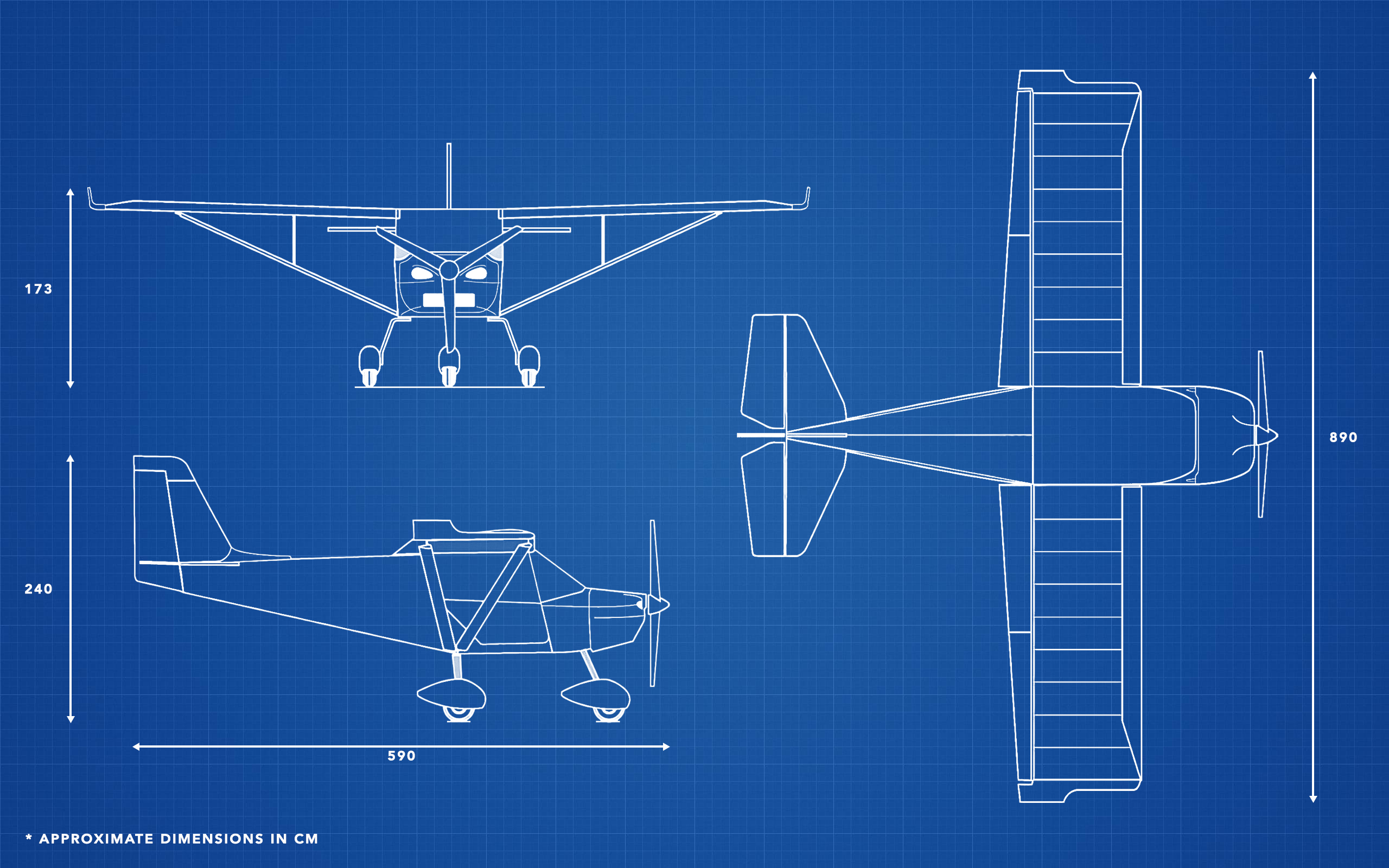

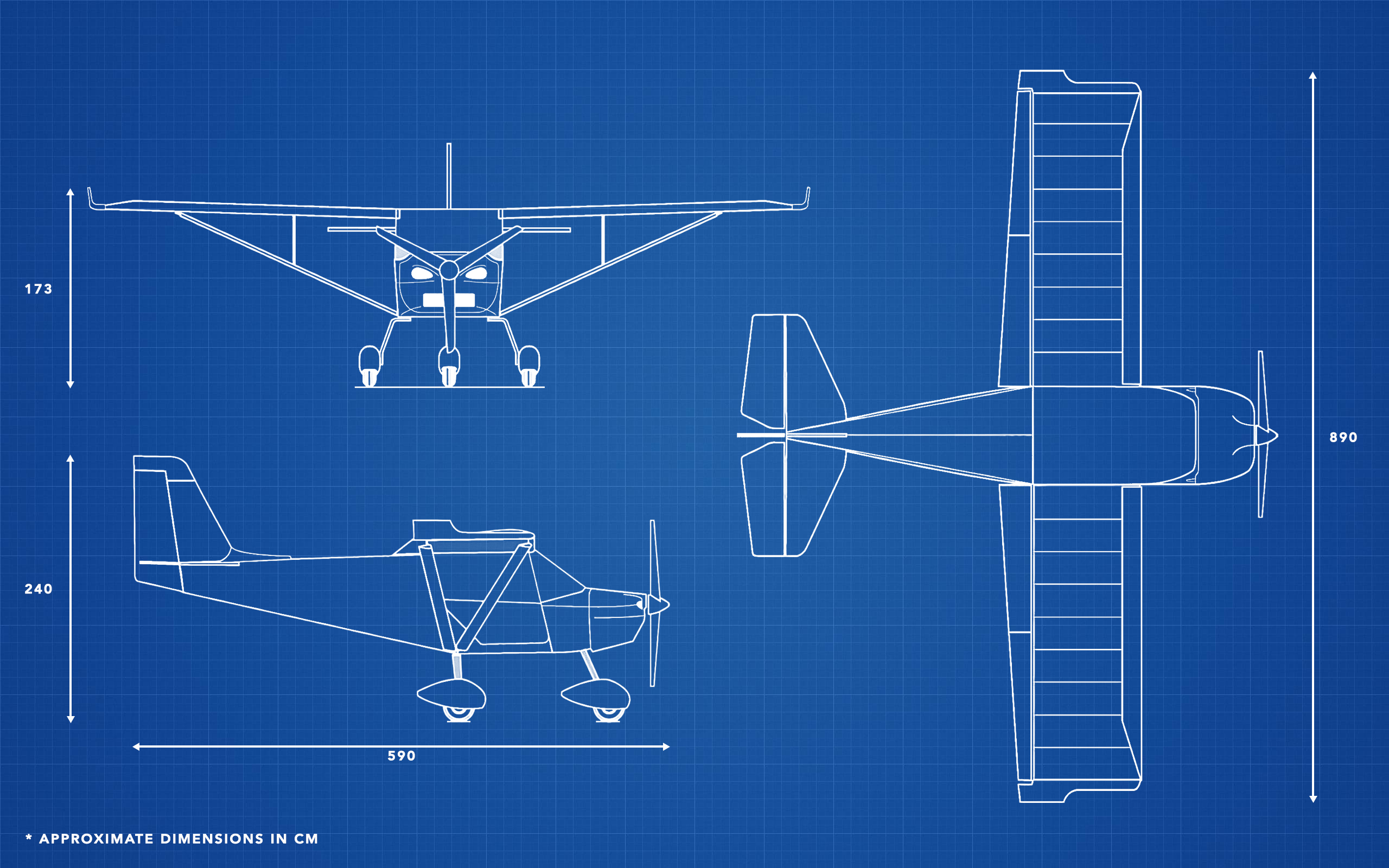

SPECIFICATIONS

AND MODIFICATIONS

Engine:

Rotax 912is 1200cc 4-cylinder fuel-injected petrol engine

Wing span:

Length:

Fuselage width:

Height:

Max take-off weight:

Empty weight:

Max speed:

Cruise speed:

Stall speed:

Take-off distance:

Range (typical):

8.9m

5.9m

1.09m

2.4m

600kg

300kg

113kts (130mph)

80kts (90mph)

33kts (38mph)

160m

300-400 nautical miles

(350-450 miles)

Engine:

Rotax 912is 1200cc 4-cylinder fuel-injected petrol engine

Wing span:

Length:

Fuselage width:

Height:

Max take-off weight:

Empty weight:

Max speed:

Cruise speed:

Stall speed:

Take-off distance:

Range (typical):

8.9m

5.9m

1.09m

2.4m

600kg

300kg

113kts (130mph)

80kts (90mph)

33kts (38mph)

160m

300-400 nautical miles

(350-450 miles)

Engine:

Rotax 912is 1200cc 4-cylinder fuel-injected petrol engine

Wing span:

Length:

Fuselage width:

Height:

Max take-off weight:

8.9m

5.9

1.09m

2.4m

600kg

Empty weight:

Max speed:

Cruise speed:

Min speed:

Take-off distance:

Range (typical):

300kg

113kts (130mph)

80kts (90mph)

33kts (38mph)

160m

300-400 nautical miles

(350-450 miles)

Engine:

Rotax 912is 1200cc 4-cylinder fuel-injected petrol engine

Wing span:

Length:

Fuselage width:

Height:

Max take-off weight:

8.9m

5.9

1.09m

2.4m

600kg

Empty weight:

Max speed:

Cruise speed:

Min speed:

Take-off distance:

Range (typical):

300kg

113kts (130mph)

80kts (90mph)

33kts (38mph)

160m

300-400 nautical miles

(350-450 miles)

MODIFICATIONS

Explore my planned modifications below!

To read more about these modifications, head over to the Modifications article on my blog.

FUEL-INJECTED ENGINE

Whilst the majority of Skyrangers are fitted with carbureted engines, we intend to fit the Rotax 912is – a fuel injected engine – to improve reliability and fuel burn.

WING FUEL TANKS

The standard Nynja stores its fuel in twin fuel tanks directly behind the crew. We intend to fit additional tanks in the wings to allow for the carriage of additional fuel.

SATELLITE COMMUNICATIONS

We intend to explore satellite communication options to enable weather and extra-ordinary air traffic control communication capabilities.

SPECIAL OPS PERMIT

With the help of the BMAA, we will attempt to obtain a special operations permit to allow us to occasionally operate above the usual weight limitations in order to carry additional fuel for the ultra-long legs of our trip.

FUEL-INJECTED ENGINE

Whilst the majority of Skyrangers are fitted with carbureted engines, we intend to fit the Rotax 912is – a fuel injected engine – to improve reliability and fuel burn.

WING FUEL TANKS

The standard Nynja stores its fuel in twin fuel tanks directly behind the crew. We intend to fit additional tanks in the wings to allow for the carriage of additional fuel.

SATELLITE COMMUNICATIONS

We intend to explore satellite communication options to enable weather and extra-ordinary air traffic control communication capabilities.

SPECIAL OPS

PERMIT

With the help of the BMAA, we will attempt to obtain a special operations permit to allow us to occasionally operate above the usual weight limitations in order to carry additional fuel for the ultra-long legs of our trip.

BUILD PROGRESS

REAR FUSELAGE IN PROGRESS

NOVEMBER 2025

My microlight is starting to look like a plane!

I’ve constructed the rear fuselage section, and installed the steel bracing cables.

Completed(-ish) front fuselage section [ Oct 25 ]